QUALITY CONTROL

Committed to continuous improvement and technological advances of all quality processes.

QUALITY CONTROL

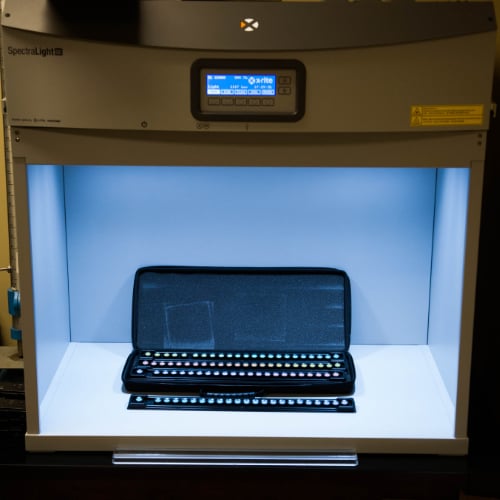

Liberty Plastics quality control system, conveys our ability to constantly provide the highest quality products while meeting customer requirements. We aim to enhance customer satisfaction through our high-quality materials, cutting-edge equipment and effective application of systems processes.

Our commitment to continuous improvement and technological advances allow us to meet your most precise plastic injection molding requirements.

To ensure continuous improvement, Liberty Plastics determines, collects and analyzes appropriate data to demonstrate the suitability and effectiveness of each process. This data is generated as a result of monitoring and measurement of processes and products.

We guarantee product quality by minimizing the variables and inconsistencies within our plastic injection molding manufacturing process by using:

- First Piece Approval

- In Process Quality Checklists

- Installation Qualifications

- Operational Qualifications

- Product Capability Qualifications

- Process Qualifications

QUALITY POLICY

“We shall strive for total customer satisfaction by continuously improving the quality, speed and responsiveness of all our business activities.”

“Our goal is to deliver defect-free, premium-value products on time, with service second to none.”

ISO 9001:2015 CERTIFIED

Liberty Plastics is ISO Certified to the 9001:2015 Standards. We take pride in our ability to provide the highest quality plastic injection molded products, that meet or exceed customer expectations.